GENERAL CHARACTERISTICS OF CONVEYORED TEMPERING FURNACES:

|

Energy Type |

Natural Gas - LPG - Electric |

|

Insulation |

Combination of high temperature insulation bricks - Z block ceramic fiber - Rockwool - Ceraboard |

|

Control |

Standart Automatic Designed with 2 thermocouples. One for heat control, one for overheatr System failures can be monitored by the warning lights located on the control panel PID. temperature control system (electric heating systems) Silent and long lasting SSR system (electric heating systems) Optional Different programs can be entered via programming device. (optional) Touch screen control panel PLC control system with touch screen panel Temperature detection and monitoring from different points in the furnace Process curves can be saved in a computer and print outs can be taken if needed Proportional burner control systems (Natural Gas - LPG) Belt speed can be adjusted via FC (frequency convertor) |

| Advantages |

Custom designed furnaces according to your needs and expectations Our furnaces offer long service life as a result of their rigid design and high quality materials . By using high quality insulation materials and adequate number of layers energy costs are decreased significantly . Bemaktherm will keep supporting his customers in order the run their furnaces flawlessly. |

| Optional |

Steel Belt Conveyor Chain Conveyorr Cooling section Multiple heating zones |

GENERAL CHARACTERISTICS OF CONVEYORED TEMPERING FURNACES

| INNER DIMENSIONS | : 1000 X 12.000 X 300 mm |

| ENERGY TYPE | : Natural Gas |

| MAX. TEMPERATURE | : 500 °C |

| CONTROL | : Belt speed can be adjusted via the control panel. |

Temperature control can be done separately via 4 zones.

Maximum temperature homogeneity is ensured with proportionally controlled burners and circulation fans.

There is a cooling tunnel at the exit of the oven that brings the products to ambient temperature.

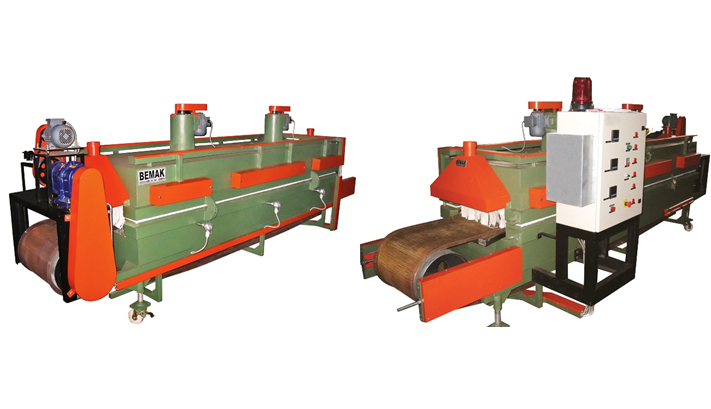

STEEL BELT CONVEYORED TEMPERING FURNACE

| INNER DIMENSIONS | : 1000 X 18.000 X 30 mm |

| ENERGY TYPE | : Natural Gas |

| MAX. TEMPERATURE | : 650 °C |

| CONTROL | : Temperature control can be done separately via 4 zones. |

Maximum temperature homogeneity is ensured with proportionally controlled burners and circulation fans.

The system has been designed as a complete system with Steel Belt Conveyored Tempering Furnace and Roller Conveyored Annealing Furnace..

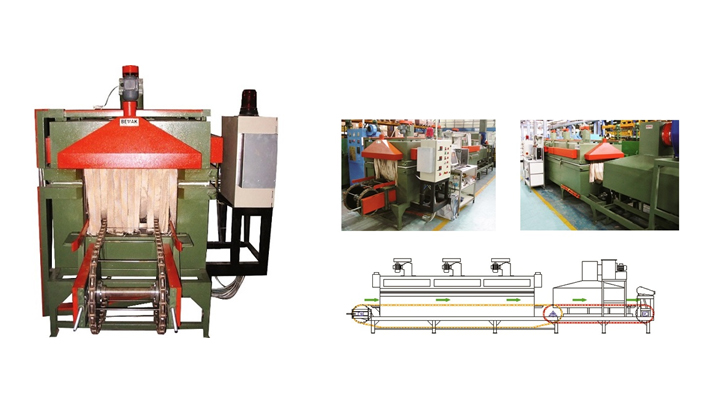

TEMPERING FURNACE (STEEL BELT CONVEYORED)

| INNER DIMENSIONS | : 1250 X 13000 X 300 mm |

| ENERGY TYPE | : Natural Gas |

| MAX. TEMPERATURE | : 500 °C |

| CONTROL | : Belt speed can be adjusted via the control panel.. |

Temperature control can be done separately via 4 zones.

Furnace has a muffle and circulation system for maximum homogenity.

ANNEALING FURNACE (ROLLER CONVEYORED)

| INNER DIMENSIONS | : 1000 X 9000 X 300 mm |

| ENERGY TYPE | : Natural Gas |

| MAX. TEMPERATURE | : 1000 °C |

| CONTROL | : Belt speed can be adjusted via the control panel. |

STEEL BELT CONVEYORED TEMPERING FURNACE

| INNER DIMENSIONS | : 500 X 3000 X 180 mm |

| ENERGY TYPE | : Elektric |

| MAX. TEMPERATURE | : 450 °C |

| CONTROL | : Automatic - Programmable |

Belt speed can be adjusted via the control panel.

Temperature control can be done separately via 3 zones.

With PID control, each zone can be programmed by ± 5 ºC tolerance

CHAIN CONVEYORED TEMPERING FURNACE

| INNER DIMENSIONS | : 900 X 4000 X 450 mm |

| ENERGY TYPE | : Elektric |

| MAX. TEMPERATURE | : 450 °C |

| CONTROL | : Automatic - Programmable |

Furnace is chain conveyored. Loading is done via metal boxes placed on the chain conveyor.

Furnace is composed of 3 heating sections that can be controlled separately.

With PID. control each section can be programmed with ± 5 ºC tolerance.

A cooling tunnel is designed after the heating section, to cool down the material to a hand-touchable temperature.

Belt speed can be adjusted from the control panel.