GENERAL CHARACTERISTICS OF CONVEYORED FURNACES:

|

Energy Type |

Natural Gas - LPG - Electrick |

|

Insulation |

High density rockwool - glass wool - ceramic fiber |

|

Control |

Standart Automatic Designed with 2 thermocouples; One for heat control, one for overheat System failures can be monitored by the warning lights located on the control panel. PID. temperature control system (electric heating systems) Silent and long lasting SSR system (electric heating systems) Optional Different programs can be entered via programming device. (optional) Touch screen control panel PLC control system with touch screen panel Temperature detection and monitoring from different points in the furnace Process curves can be saved in a computer and print outs can be taken if needed Proportional burner control systems (Natural Gas - LPG) |

| Advantages |

Custom designed furnaces according to your needs and expectations Our furnaces offer long service life as a result of their rigid design and high quality materials By using high quality insulation materials and adequate number of layers energy costs are decreased significantly Bemaktherm will keep supporting his customers in order the run their furnaces flawlessly. |

CHAIN CONVEYORED HYDROGEN EMBRITTLEMENT RELIEF FURNACE WITH ELEVATOR SYSTEM

| CAPACITY | : 1000 kg / h |

| ENERGY TYPE | : Natural Gas |

| MAX. TEMPERATURE | : 250 °C |

| CONTROL | : PLC CONTROLLED |

Designed for eliminating hydrogen embittlement brittleness in fasteners industry.

With the help of an effective circulation system (distribution and collection channels) maximum homogenity in the furnace is reached.

With PLC control system;

Conveyor speed

Multiple temp. readings within furnace,

Position of the product inside the furnace,

Process curves

Can be adjusted.

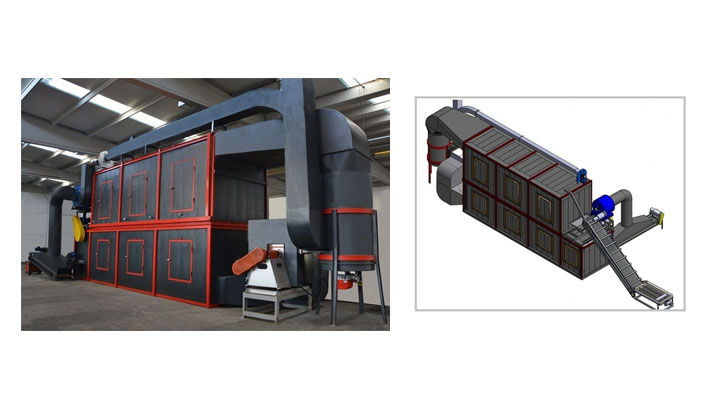

3 FLOOR - STEEL BELT CONVEYORED HYDROGEN EMBRITTLEMENT RELIEF FURNAC

| CAPACITY | : 1200 kg / h |

| ENERGY TYPE | : Natural Gas |

| MAX. TEMPERATURE | : 250 °C |

| CONTROL | : PLC CONTROLLED |

Designed for eliminating hydrogen embittlement brittleness in fasteners industry.

With the help of an effective circulation system (distribution and collection channels) maximum homogenity in the furnace is reached.

With PLC control system;

Conveyor speed

Multiple temp. readings within furnace,

Position of the product inside the furnace,

Process curves

Can be adjusted.

3 FLOOR - STEEL BELT CONVEYORED HYDROGEN EMBRITTLEMENT RELIEF FURNACE

| CAPACITY | : 1200 kg / h |

| ENERGY TYPE | : Natural Gas |

| MAX. TEMPERATURE | : 250 °C |

| CONTROL | : PLC CONTROLLED |

Designed for eliminating hydrogen embittlement brittleness in fasteners industry.

With the help of an effective circulation system (distribution and collection channels) maximum homogenity in the furnace is reached.

With PLC control system;

Conveyor speed

Multiple temp. readings within furnace,

Position of the product inside the furnace,

Process curves

Can be adjusted.